Capabilities

With our state-of-the-art facility, wide range of ready-for-production materials in house, multiple plating options, and heat treat capabilities, Prestige is able to provide the highest quality domestic washers along with the highest service levels to our customers.

We’ve earned the name prestige.

- Millions of pounds of prime, fully traceable material in-stock and ready for production

- Technology-enhanced custom tooling along with thousands of standard tool combinations

- High-speed press room delivers ranges from 35 to 250 tons

- State-of-the-art production management system, optimizes performance, reporting, certification, and rapid turnaround

- IATF16949 and ISO9001 certified

- Caterpillar platinum supplier

- GM platinum supplier

State-of-the-Art Facility

- 102,000 square foot facility

- 22 high speed presses (35-250 ton capacity)

- Eight automated / digital sorting machines

- Coil material from .020” through .375”

- Full design and build tool department

- Prestige builds and maintains master dies that run majority of the washers we manufacture

- Greatly minimizes tool costs in most situations

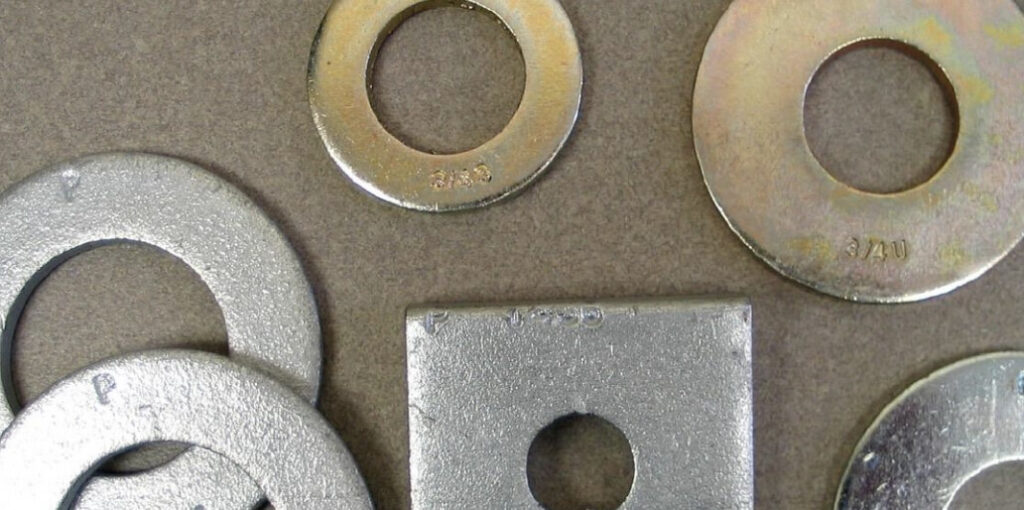

Wide Range Of Materials

- Steel grades – SAE-1008 to 1075

- Copper

- Brass

- Aluminum

- Pre-tempered and stainless steel

- Most high strength materials

Heat Treating Processes

- Case hardening

- Carbonitriding

- Through hardening

- Surface hardening

- Bright annealing

- Austempering (External)

Choice Of Plated Finishes

- Zinc

- Copper

- Nickel

- Anodizing

- Phosphate

- Organic coatings

- Dacromet

- Mechanical and hot dip galvanizing